Piano hinges, also known as continuous hinges, were created to join two flat surfaces together, typically at a 180-degree angle. These surfaces can be made of a variety of materials, including wood, metal, and plastic. The design of the piano hinge allows for a smooth and even distribution of weight and stress along the entire length of the hinge. The name “piano hinge” comes from its use in piano lids, which require a strong and flexible hinge to withstand the weight of the lid while allowing for easy opening and closing. Today, piano hinges are used in a wide variety of applications beyond pianos, and are a popular choice for many different industries and projects Read More…

We take our customer evaluations as our only measure of success. If our customers are not happy, we are not happy! We will work with you until we find the right hinges solution for you.

Brookfield Industries is a manufacturer of high-capacity door hinges and pivots. We also manufacture special application door operators with a full-line of detention grade and industrial stainless steel hinges with capacities ranging from 300 lbs to 50 tons. We offer seven categories of hinges, and within those categories we offer several subcategories – we can meet your company’s hinge needs.

We are here to provide you with any hinge you could ever possibly need! We are the hinge specialists committed to bringing you a level of customer service that is unmatched by the competition.

Hardware Mfg. supplies stock inventory parts in addition to creating custom components for OEM and resellers. We work with a number of different industries such as agriculture, drug tablet, livestock, truck equipment, conveyors, and more.

Specializing in custom-made hinges is what Hinge & Hardware is known for. We also stock certain types of standard models to round out the availability for our customers. The aforementioned are available as mild steel, aluminum and stainless. We also have a wider hardware line that includes door seals, gaskets, handles, a variety of latches and enclosure hardware.

More Piano Hinge Manufacturers

Components of Piano Hinges

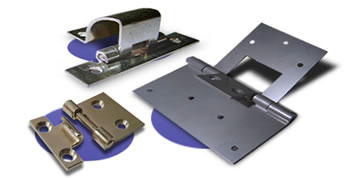

Piano hinges consist of two leaf plates, connected by a pin that runs the length of the hinge. The leaf plates are the long, flat pieces that are attached to the surfaces being joined. The pin is the cylindrical rod that connects the leaf plates and allows for rotational movement. The knuckles are the cylindrical portions of the hinge that surround the pin and connect the leaf plates. Finally, the flange is the portion of the hinge that is attached to the surface, providing support and stability.

Variations of Piano Hinges

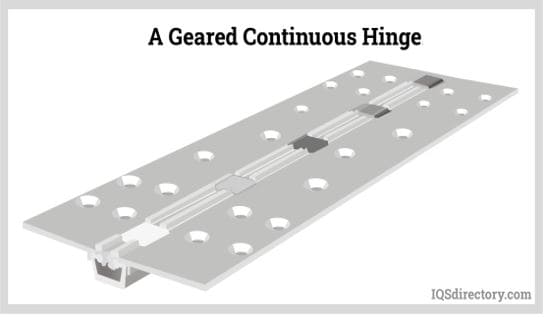

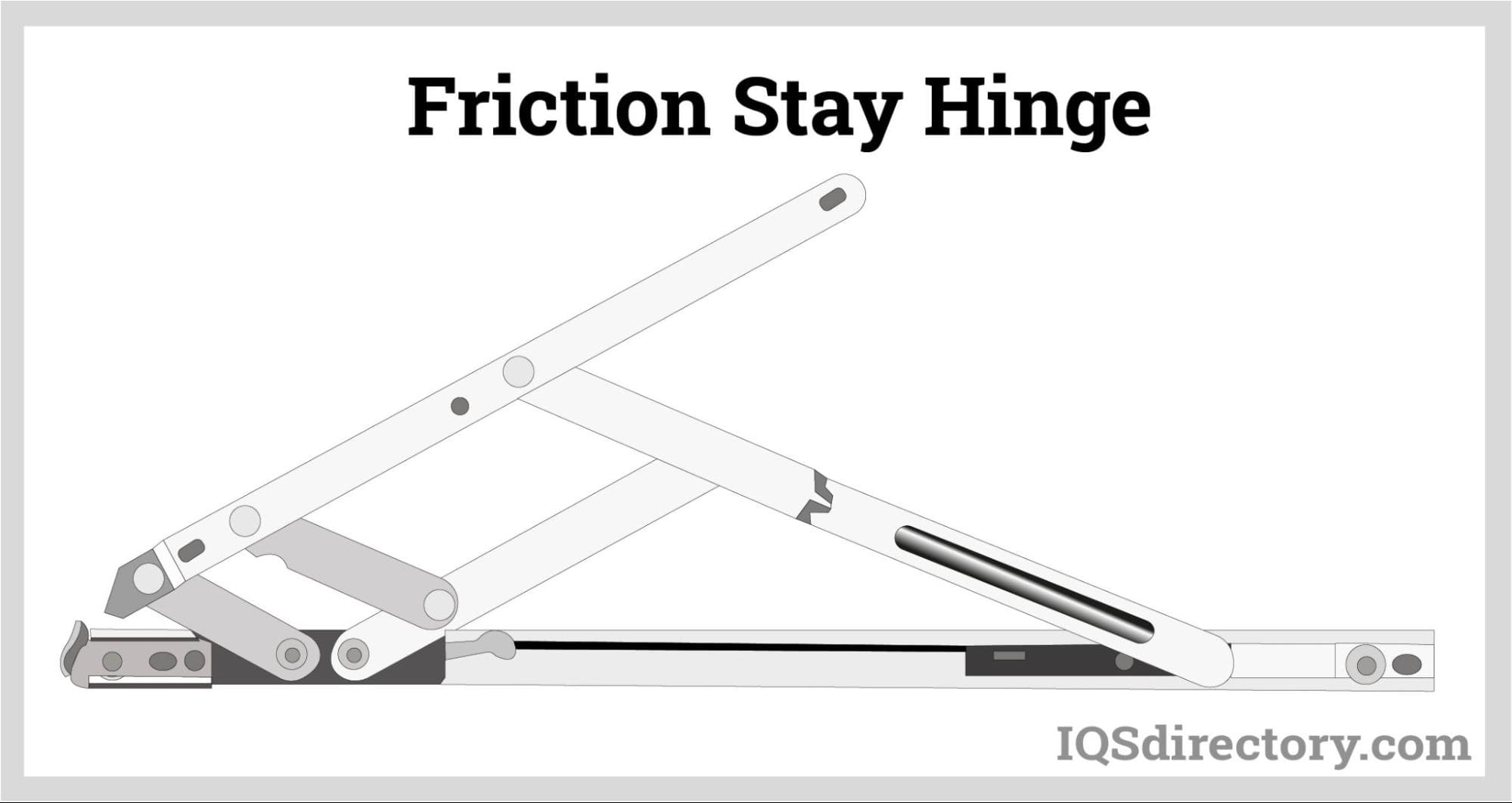

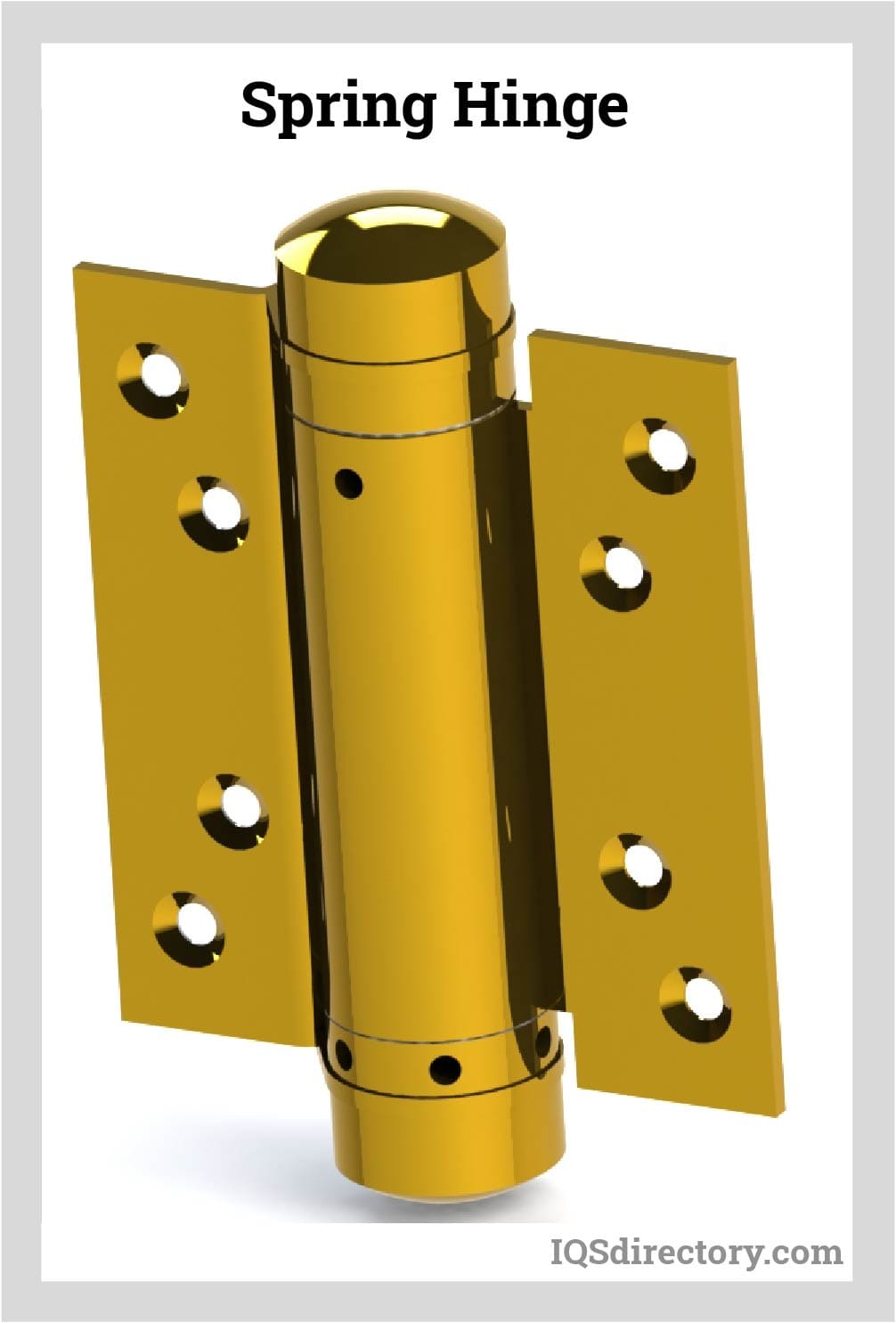

There are several variations of piano hinges, each with unique features and applications. Continuous hinges are the most common type of piano hinge, consisting of a single long piece of metal that runs the length of the joint. Strap hinges are similar to continuous hinges, but are wider and have a more decorative appearance. Concealed hinges are designed to be hidden from view, often used in cabinetry and furniture applications. Specialty hinges include take-apart hinges, which can be easily disassembled, and offset hinges, which allow for the hinge to be offset from the surface it is attached to.

Materials Used for Piano Hinges

Piano hinges are commonly made from stainless steel, brass, aluminum, and plastic. Stainless steel is the most popular material due to its high strength and durability, as well as its resistance to corrosion and rust. Brass is a popular choice for decorative applications due to its attractive appearance, while aluminum is commonly used in lightweight applications such as aerospace and automotive industries. Plastic piano hinges are used for low-stress applications and offer a cost-effective alternative to metal hinges.

Considerations for Piano Hinges

While piano hinges offer many benefits, there are also some limitations to consider. The weight capacity of piano hinges can be a concern, as they are not designed to handle heavy loads. They are also susceptible to rust and corrosion if not made from the proper material, and their flexibility is limited compared to other types of hinges.

Benefits of Piano Hinges

Despite their limitations, piano hinges offer many benefits. They are easy to install and offer a high level of strength and durability. Their aesthetic appeal makes them popular in furniture and decorative applications, and their versatility and flexibility make them useful in a wide variety of industries and applications.

Applications of Piano Hinges

Piano hinges are used in a wide variety of applications, including:

Furniture

Piano hinges are commonly used in furniture applications where a hinge is needed to allow for rotational movement. They are often used in desks, cabinets, tables, and other pieces of furniture. Due to their aesthetic appeal and versatility, piano hinges are a popular choice in furniture design.

Doors

Heavy-duty doors and fire doors often use piano hinges due to their strength and durability. They are also commonly used in cabinet doors, wardrobe doors, and other interior doors.

Automotive

In the automotive industry, piano hinges are used in trunks, glove boxes, and other applications where a hinge is needed. They are also used in convertible tops, sunroofs, and other automotive accessories.

Aerospace and Defense

In the aerospace and defense industries, piano hinges are used in aircraft interiors, such as overhead storage bins and lavatory doors. They are also used in military vehicles, such as troop carriers and tanks.

Marine and Boating

In the marine and boating industry, piano hinges are used in hatch covers, cabinetry, and other applications. They are also used in boat doors, hatches, and windows.

Other Applications

Piano hinges are used in a variety of other applications, including industrial equipment, toolboxes, and medical equipment. They are also used in the construction industry, for example, to connect panels or siding to a structure.

Choosing the Correct Piano Hinge Manufacturer

To ensure you have the most constructive outcome when purchasing piano hinges from a piano hinge manufacturer, it is important to compare several companies using our directory of piano hinge manufacturers. Each piano hinge manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each piano hinge business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple piano hinge manufacturers with the same form.

Bolts

Bolts Fasteners

Fasteners Gas Spring

Gas Spring Handles

Handles Hinges

Hinges Latches

Latches Locks

Locks WIre Hooks

WIre Hooks Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services