Marine hinges are a specially designed hinge that is approved for installation on boats, ships, and equipment for use in ocean and lake environments. These simple flat mechanisms have to meet a set of strict standards before being approved for marine use. Each part of the mechanism has to be certified and approved down to the smallest detail. Read More…

We take our customer evaluations as our only measure of success. If our customers are not happy, we are not happy! We will work with you until we find the right hinges solution for you.

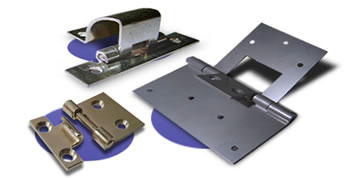

Brookfield Industries is a manufacturer of high-capacity door hinges and pivots. We also manufacture special application door operators with a full-line of detention grade and industrial stainless steel hinges with capacities ranging from 300 lbs to 50 tons. We offer seven categories of hinges, and within those categories we offer several subcategories – we can meet your company’s hinge needs.

We are here to provide you with any hinge you could ever possibly need! We are the hinge specialists committed to bringing you a level of customer service that is unmatched by the competition.

Hardware Mfg. supplies stock inventory parts in addition to creating custom components for OEM and resellers. We work with a number of different industries such as agriculture, drug tablet, livestock, truck equipment, conveyors, and more.

Specializing in custom-made hinges is what Hinge & Hardware is known for. We also stock certain types of standard models to round out the availability for our customers. The aforementioned are available as mild steel, aluminum and stainless. We also have a wider hardware line that includes door seals, gaskets, handles, a variety of latches and enclosure hardware.

More Marine Hinge Manufacturers

The first step in the manufacture of marine hinges is the selection of the type of metal. Most obviously, most metals are not appropriate for harsh wet conditions due to their propensity to rust and corrode. To provide producers with guidance and standards for the types of metals for marine use, the American Bureau of Shipping publishes a list of metals that are suitable for the manufacture of marine equipment and products.

Though marine conditions may seem restrictive, the majority of metals can be adapted to fit the conditions of a marine environment including stainless and alloyed steels to aluminum and brass. To meet the necessary specifications, metals are blended with other metals that have all of the required qualities of rust and corrosion resistance.

Common steels used for marine hinges are AH.36, DH36, and EH36, which have exceptional tensile strength, durability, and endurance. These steels are weldable and can be formed and shaped to fit any application making them perfect for use as hinges. For most producers, steel is the first choice for producing marine hinges and products.

The adapting of a metal for marine use involves the application of some form of coating. Though this may seem to be a simple process, the EPA has very strict regulations regarding the types of chemicals and compounds that are acceptable to be combined for coating materials. These requirements have caused producers to be constantly and changing their processes.

When choosing a metal and its coating, for a hinge, there are a couple factors that need to be consider. First is the positioning of the hinge, whether it will be immersed or above the water line. This factor determines if the metal will need treatment beyond a coating, which could include cathodic treatment.

A normal process used to condition selected metal hinges for marine use is anodizing, a process that produces an oxide layer on the hinge. As has been found with aluminum, an oxide layer is rust and corrosion resistant. The anodizing process creates a hard, long wearing coating that enhances the hardness and strength of certain metals.

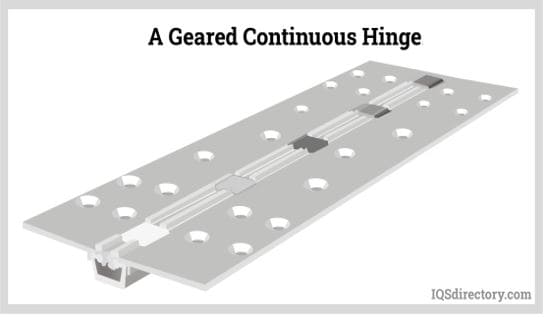

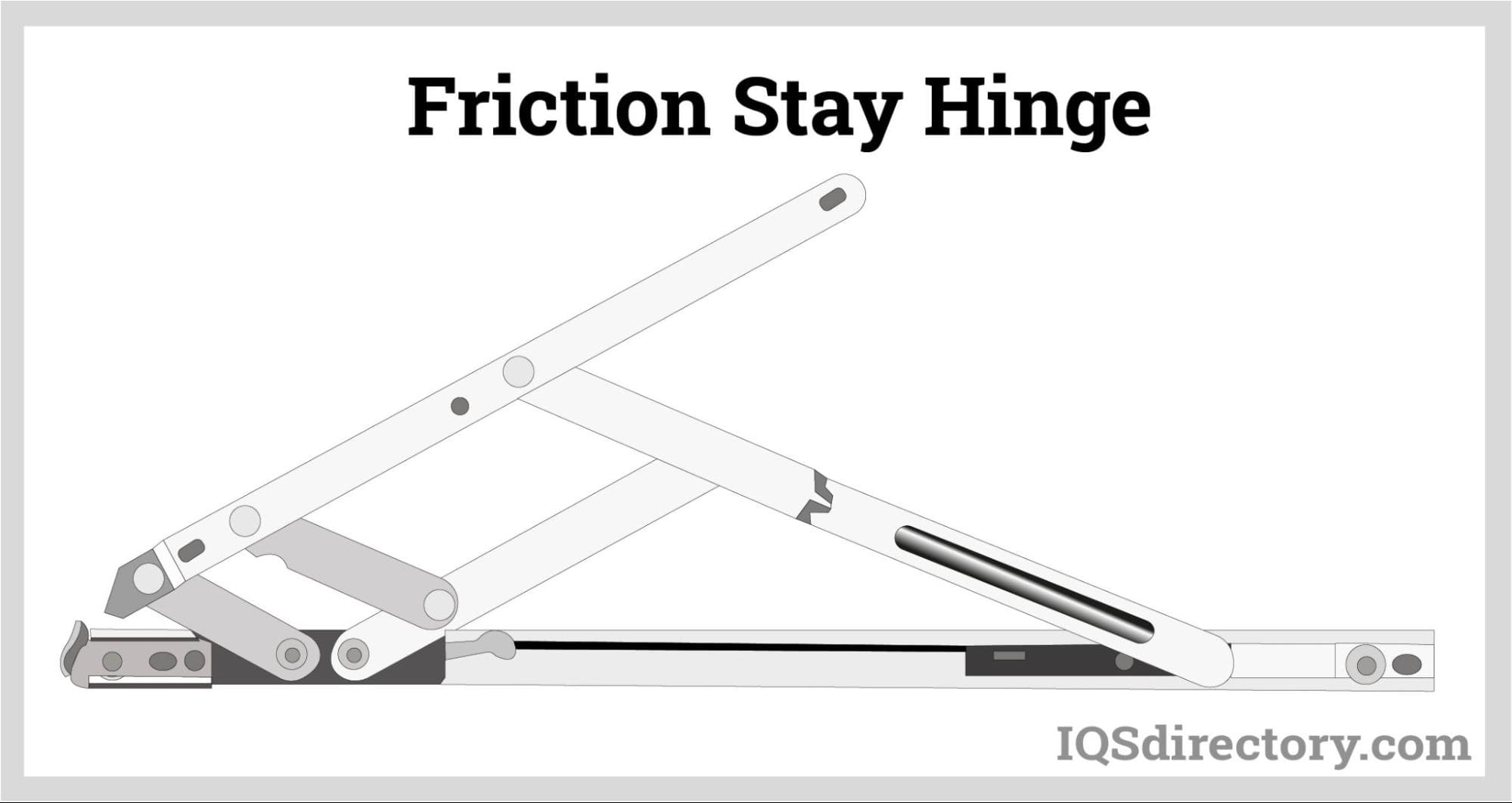

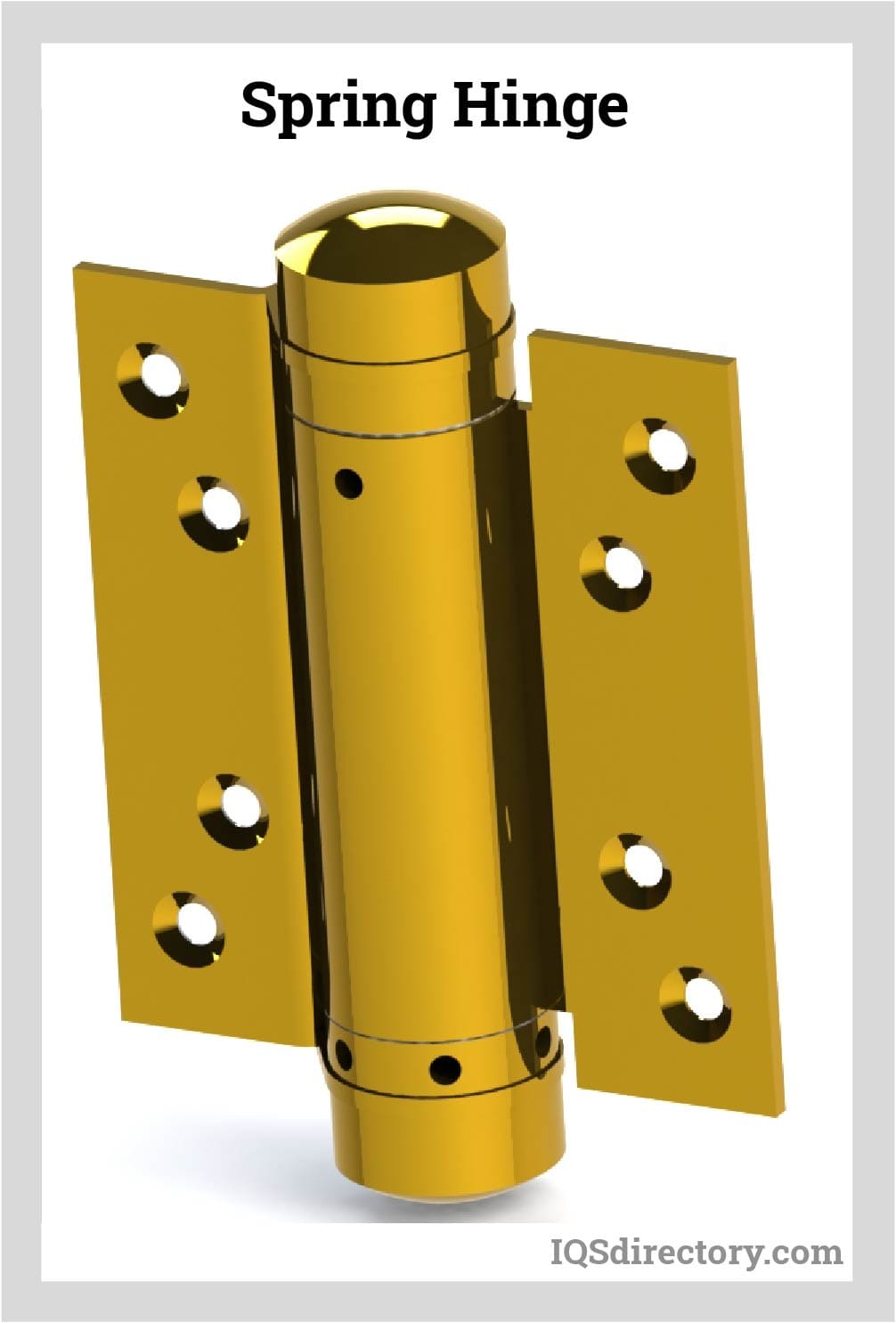

There are a wide variety of hinges that include butt, piano, glass, concealed, or mounted. Though they are normally found in other applications, they have to be specially conditioned for marine applications. Unlike their hardware store counterparts, they are more expensive due to the processing necessary to make them adaptable for marine conditions.

Bolts

Bolts Fasteners

Fasteners Gas Spring

Gas Spring Handles

Handles Hinges

Hinges Latches

Latches Locks

Locks WIre Hooks

WIre Hooks Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services